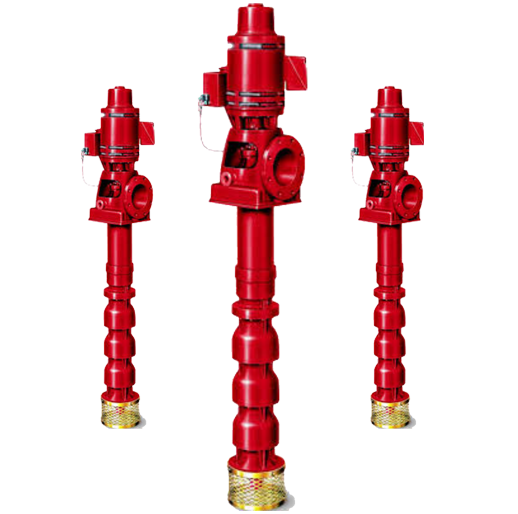

Vertical Turbine Fire Pumps

Compete Unit responsibility.

Complete in-house favrication capabilities.

Hydrostatic strength testing facilities.

Performance as per NFPA 20, UL 448 requirements.

Vertical turbine models for capacities from 50 to 1000 us GPM.

Drivers: Electric motor drive or diesel engine drive.

Electrical testing capabilities for mortors and controllers as per NFPA standards.

Capable to supply additional accessories where ever required.

Rugged construction for longer service life.

Specifically designed for fire fighting applications as per NFPA 20.

Excellent mechanical and hydraulic design characteristics for efficient performance.

Suction bell is furnished with an extra long bearing that strengthens and providers rigid support for the lower end of the pump shaft. Suction bell provides efficient flow into the eye of the first stage impeller.

Impellers are enclosed type, made of bronze / SS 304 and matched to the pump bowls, each impeller is statically / dynamically balanced as per ISO 1940-1 to insure highest efficiency and vibration free operation.

The rugged pump discharge head assembly is made of close-grained cast iron. It has smooth passageways that ensures efficient overall operation piping.

Pump column pipe shall be in section not longer than 10ft each. Column pipe is flanged type. Flanged connections are accurately machined to accept bearing retainers and are bolted together security for proper sealing.

The pump bowls have vanes cast integrally in them. These vanes are designed to match accurately with the impeller, and are smoothly contoured to guide the flow to next stage with maximum efficiency.

The shaft sealing is gland packing type. A lantem ring is fumished between the packing and it relieves pupm pressure from the upper packing rings by bypassing the high pressure water through its relief ports.

| Sr. No. | Pump Model | UL Listed Pressure (PSI) | Rated Speed (RPM) | Discharge Outlet Dia. (mm) | Stages |

|---|---|---|---|---|---|

| 1 | SUAC-500 | 80-150 | 1450 | 150 | 3 |

| 2 | SUAC-500A | 84-215 | 1450 | 150 | 4-8 |